Image Credit: 3Dalia/Shutterstock.com

Given the environmental and security issues surrounding it, the nuclear power industry is facing unprecedented problems. The current state of the industry is largely built on legacy technology and processes, but the recent adoption of 3D printing could revolutionize nuclear power and reverse the industry’s troubling trends.

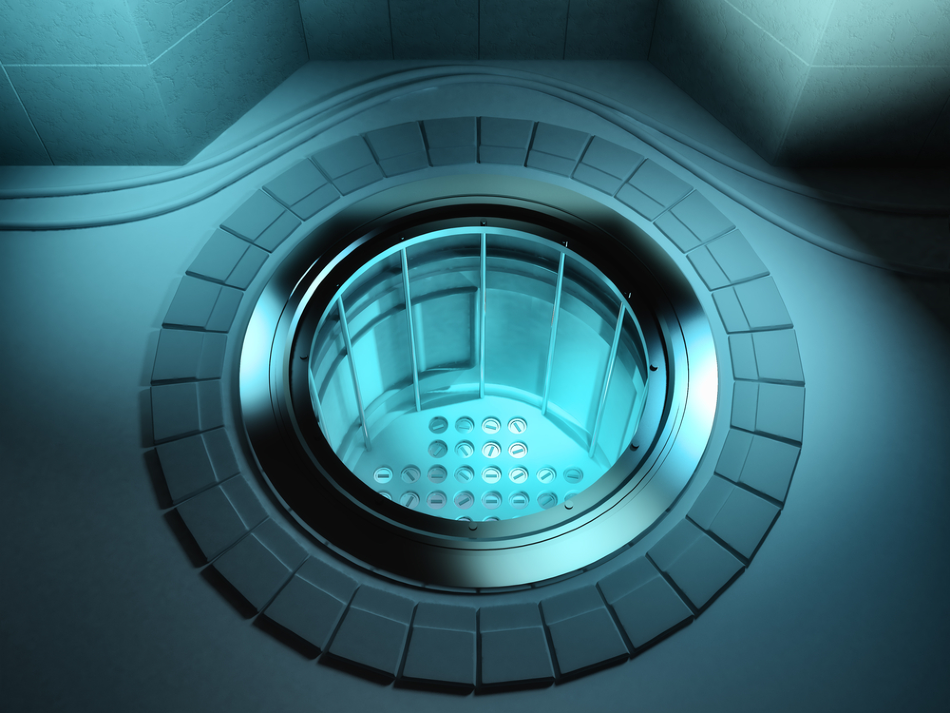

A 3D-printed reactor core is being developed through the Transformational Challenge Reactor (TCR) project at the Oak Ridge National Laboratory (ORNL), a US Department of Energy facility.

TCR researchers are improving designs for a 3D-printed reactor core, ramping up the fabrication process and establishing procedures to verify the uniformity and dependability of printed components.

The ORNL said the plan is to switch on a 3D-printed reactor by 2023. Despite the COVID-19 pandemic and quarantine, the lab has so far sustained its original timeline, designing and evaluating program aspects remotely.

ORNL explores the possibilities of a 3D-printed nuclear reactor

Video Credit: Oak Ridge National Laboratory/YouTube.com

Nuclear Energy in the US

For decades, the development and implementation of nuclear reactor technology has incorporated building materials, source material and various technologies developed in the mid-1900s. High costs, heavy regulation and extensive construction times have constrained the building of new nuclear facilities in the United States, with just one plant being built in the last 20 years.

According to license expiration dates, more than half of all reactors in the United States are slated for retirement within the next two decades. Nuclear power currently represents around 20% of all electricity produced in the country.

While nuclear power is not without troubling environmental impacts, advocates argue that the technology does produce low-emissions electricity, especially compared with fossil fuel power facilities.

3D Technology and its Use in the Nuclear Industry

Using 3D technology to design and fabricate nuclear technology such as spare parts and prototypes may help to lower costs, as modifications to 3D digital prototypes only require minor programming adjustments.

In 2017, Siemens announced the first commercial installation of a 3D-printed nuclear power part. This achievement was particularly notable because of the strict regulatory and safety guidelines associated with this industry. Nuclear technology has to be sturdy, dependable and temperature resistant. There are strict testing processes in place to ensure every part is held up to high standards.

There have been several developments since then. The most promising application for additive manufacturing in nuclear power is in so-called microreactors, which cannot fit on a tractor-trailer. Microreactors are usually capable of generating less than 10 megawatts of power and are often used in specialized applications.

The Next Generation of Nuclear Power Technology?

The TCR plan is dedicated to launching new, sophisticated materials and making use of integrated devices to create an enhanced, efficient fabrication system that lowers cost.

The team is leveraging the latest scientific advances to inform reactor design, production and operation. It is working on a sensor system that could permit near-autonomous control, and a library of information that could be used by the entire nuclear power community.

The program has finished multiple fundamental trials, including tests related to core design and the additive manufacturing process, with the latter featuring the technology’s capacity to quickly generate a prototype core.

ORNL scientists have been concentrating on improving their designs and operations so they can settle on an effective and dependable system.

Click here for more information on materials-related equipment.

The team has been tracking and evaluating various additive manufacturing methods so it can qualify 3D-printed material using artificial intelligence in real-time. Monitoring systems are being used to assess the manufacturing sequence, delivering real-time data regularly.

The team has also been performing thorough post-build assessments to evaluate product performance and determine connections between part performance and live monitoring data.

A software platform to assist in managing the technology is also being developed. This should accelerate the adoption of the technology.

The First 3D-Printed Power Supply Part

While Siemens has the distinction of being the first company to install a functioning 3D-printed part within a nuclear power facility, the part was for a fire protection device, and not used for the actual creation of nuclear power.

In May 2020, Westinghouse successfully installed the first 3D-printed part used for actual power generation. The installed part was a “thimble plugging device” used to lower fuel assemblies into reactor cores.

The part was the result of a three-year collaboration between Westinghouse and Exelon Generation. A thimble plugging device is essential to the production of nuclear power, but it was deemed a low-risk part because there would be minimal consequences if the part malfunctioned.

References and Further Reading

Oak Ridge National Laboratory (2020) 3D-printed nuclear reactor promises faster, more economical path to nuclear energy. [Online] Available at: https://www.ornl.gov/news/3d-printed-nuclear-reactor-promises-faster-more-economical-path-nuclear-energy (Accessed on 22 May 2020).

Conca, J (2020) 3D Printing Has Entered The Nuclear Realm. [Online] Forbes. Available at: https://www.forbes.com/sites/jamesconca/2020/05/09/3d-printing-has-entered-the-nuclear-realm/#580a2d5d7d34 (Accessed on 22 May 2020).

Essop, A. (2020) OAK RIDGE NATIONAL LABORATORY IS DEVELOPING A 3D PRINTED NUCLEAR REACTOR CORE. [Online] 3D Printing Industry. Available at: https://3dprintingindustry.com/news/oak-ridge-national-laboratory-is-developing-a-3d-printed-nuclear-reactor-core-171563/ (Accessed on 22 May 2020).

Nuclear Engineering International (2020) Westinghouse produces 3D-printed component for US nuclear plant. [Online] Available at: https://www.neimagazine.com/news/newswestinghouse-produces-3d-printed-component-for-us-nuclear-plant-7911951 (Accessed on 22 May 2020).

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.